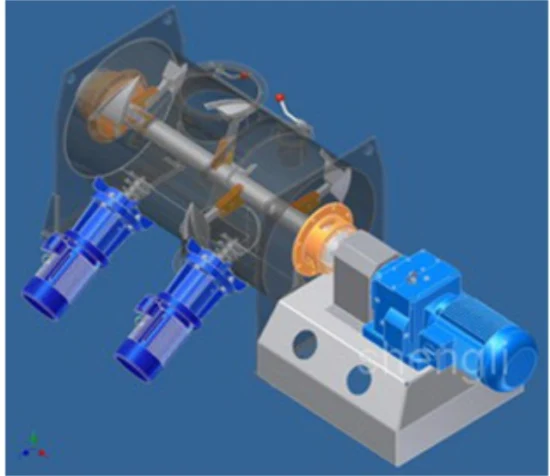

High Shear Mixer, Plow Blender for Flour, Sludge, High Speed Chopper, Cutter

Plough shear mixerWorking principles:Plough shear mixer is a single shaft compulsory mixing equipments. Several sets of ;

Basic Info

| Warranty | 1 Year |

| Size | Manufacturing by Client′s Requirement |

| Transport Package | Wooden Case or as Required |

| Specification | CE, ISO 9001 |

| Trademark | SL |

| Origin | China |

| Production Capacity | Tba |

Product Description

Plough shear mixerWorking principles:Plough shear mixer is a single shaft compulsory mixing equipments. Several sets of plough shears are installed on the main shaft in dislocation and continuously, which avoid the mixing dead zone in structure. When operating, material in mixer tank move following the direction of the continuous vortex centrifugal force generated by the continuously blending plough shears, thus to achieve scattering, dispersing and fast mixing of material.Special material like fiber or some damp agglomerate material, high speed chopper can be installed inside mixer tank to scatter, dispense these materials with combination of plough shear mixing agitator.The high speed choppers are positioned at the barrel side downward angle of 45 degrees of the plough shear mixer, the chopper heads stretch into the barrel. During mixing, materials are driven to the effective range of the chopper, and sheared in high speed by it. Powerful auxiliary components:Mixer is frequently equipped with many auxiliary components, like steam coil jacket, honeycomb pressure jacket, ,medium circulation jacket, sampling valve, high speed chopper, temperature sensor, weighing system, dust removal system and so on. Different heat medium requires different jacket, it can be used for heating and cooling, while, the temperature should be within 250 Celsius degree. If a small quantity of liquid is required during mixing, spraying or atomizing unit is necessary in order to mix the liquid evenly with the main ingredient. The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles. Tight shaft sealingThree types of main shaft sealing for mixer: packing sealing, combined type air-purged sealing, mechanical sealing are used for granule, powder, micron grade powder, liquid, and slurry material. ApplicationPlough shear mixer is designed and improved on basis of main stream mixing techniques and it is applicable for mixing multi-material.Plough shear mixer can process solid powder material, granule material, and also can process mixing in which case liquid needed to be added. This type of mixers is widely used in food, chemical, building material etc. Flexible material selectionMaterial can be choose from carbon steel, manganese steel, SS304, 316L and 321; besides, different material can also be used in combination. Material is different between the part contact with the raw material and the parts don't contact with the material. Surface treatment for stainless steel include sandblasting, wiredrawing, polishing, mirror polishing, all can be used in different parts of a mixer. Reliable driven unitThe driven unit, power and output speed are varied according to different raw material, starting method, and processing. Options for motor: general motors, explosion-proof motors, variable frequency motor, high efficiency and energy saving motor. Commonly used reducers: R-series, K-series, and F-series gear box; cycloid reducer, universal gear reducer, planetary gear reducer. Commonly used connection: direct connection, pulley connection, hydraulic coupler connection. High efficiency unit:The plow heads in the plough shear mixer can be dismountable, which is convenient for replacement. Wear-resistance treatment is done on the plough, making the plough is more adapted to the severe wear conditions. Different main shaft agitators can be equipped according to the properties of raw materials.Main shaft agitators: ordinary plough, saw-toothed plough, and shaver-shaped paddle; high speed chopper: multiple-piece cross blade, double-piece lotus blade. 5. Additional functions:Outer jacket , Heating jacket , Tube temperature-control jacket , Temperature preservation layer , Batching type , Sprinkling device, Heavy duty type.Customizing according to client's specific requirement.

| Model | Power | Speed | working capacity/ Batch | Dimension | weight |

| (kw) | (rpm) | (M3) | (mm) | (kg) | |

| LHY-0.1 | 3 | 41 | 40-60 | 1190× 740× 770 | 330 |

| LHY-0.3 | 4 | 41 | 120-180 | 2300× 680× 1060 | 550 |

| LHY-0.5 | 5.5 | 41 | 200-300 | 2900× 780× 1240 | 900 |

| LHY-1 | 11 | 33 | 400-600 | 3200× 1000× 1400 | 1600 |

| LHY-2 | 15 | 33 | 800-1200 | 3860× 1200× 1650 | 2700 |

| LHY-3 | 18.5 | 33 | 1200-1800 | 4320× 1300× 1900 | 3600 |

| LHY-4 | 22 | 27 | 1600-2400 | 4600× 1400× 2000 | 4200 |

| LHY-5 | 30 | 27 | 2000-3000 | 4850× 1500× 2020 | 5100 |

| LHY-6 | 37 | 27 | 2400-3600 | 5400× 1560× 2200 | 5600 |

| LHY-8 | 45 | 22 | 3200-4800 | 5100× 1720× 2420 | 6500 |

| LHY-10 | 45 | 22 | 4000-6000 | 5610× 1750× 2360 | 7800 |

| LHY-15 | 55 | 14 | 6000-9000 | 5820× 2000× 2900 | 11000 |

| LHY-20 | 75 | 14 | 8000-12000 | 6060× 2630× 3160 | 13000 |

| Not all products are listed. For more, please contact with the sales engineering. | |||||

You may also like

Send inquiry

Send now